Spring energized seals

Spring energized seals are a highly reliable option when standard elastomer-based and polyurethane-based seals will not meet the operating limits, equipment parameters, or environmental conditions of your application. Even when a standard seal might meet basic needs, many engineers turn to spring energized seals for an added level of reliability and peace of mind.

Spring Energized Seal Design

“Basic design parameters of spring energized seals:

1,Made from high-performance fluoroplastic compounds and engineered plastics that have outstanding physical and technical characteristics, but are rigid rather than flexible.

2,Use springs to provide a consistent load throughout the circumference of the seal and create a leak-tight seal between the jacket and the hardware.

3,Use system pressure to create an additional sealing force between the jacket and the hardware.

4,In this combination, the spring forces the seal lips against the gland and rod surfaces, while pressure assists the spring force.

5,The result: virtual leak-free sealing, high reliability, longer asset life.”

Where to Use Spring Energized Seals?

Outstanding physical features and technical characteristics make spring energized seals the ideal choice in wide variety of critical industrial equipment and applications.

Spring energized seals can be used in both dynamic and static applications. Dynamic applications cover reciprocating (linear), rotary, and oscillating movements or any combination.”

“Considerations when determining whether to use standard polymeric seals or spring energized seals include:

Temperature (operating and ambient possible maximum/minimum)

Operating pressure (what is not necessarily the maximum pressure in the system)

Velocity (moving speed)

Media (chemical compatibility: especially important in case of aggressive medias)

Friction level and wear

Environment (for example, abrasive conditions)

Application and operation of the equipment

Seal cavity configuration

Shelf-life limitation”

How Do Spring Energized Seals Work?

“

Spring energized seals are generally manufactured from high-performance fluoroplastic compounds and engineered plastics.

Typical material grades are:

PTFE (virgin and filled versions)

PEEK compounds (unfilled and filled versions)”

These materials have outstanding physical and technical characteristics, but they are not elastic. They are better characterized as rigid. That is the reason why different type of springs must be used to mechanically energize the seal lips. So the technical term “Spring Energized Seal” reflects on the design/construction of the sealing device, where the spring compensates for polymer materials with low memory/elasticity.

The Benefits of Fluoroplastic Seal Jackets

“Fluoroplastic (i.e., PTFE-based) materials are the most commonly used seal jacket material. They have outstanding physical and chemical features combined with moderated cost and good machine-ability.

With usage of different fillers, properties of PTFE compounds can be improved further related to seal performance (such as tensile strength, wear resistance, etc.). But not all properties can be increased significantly. Filler content is typically between 5% and 40% by weight.”

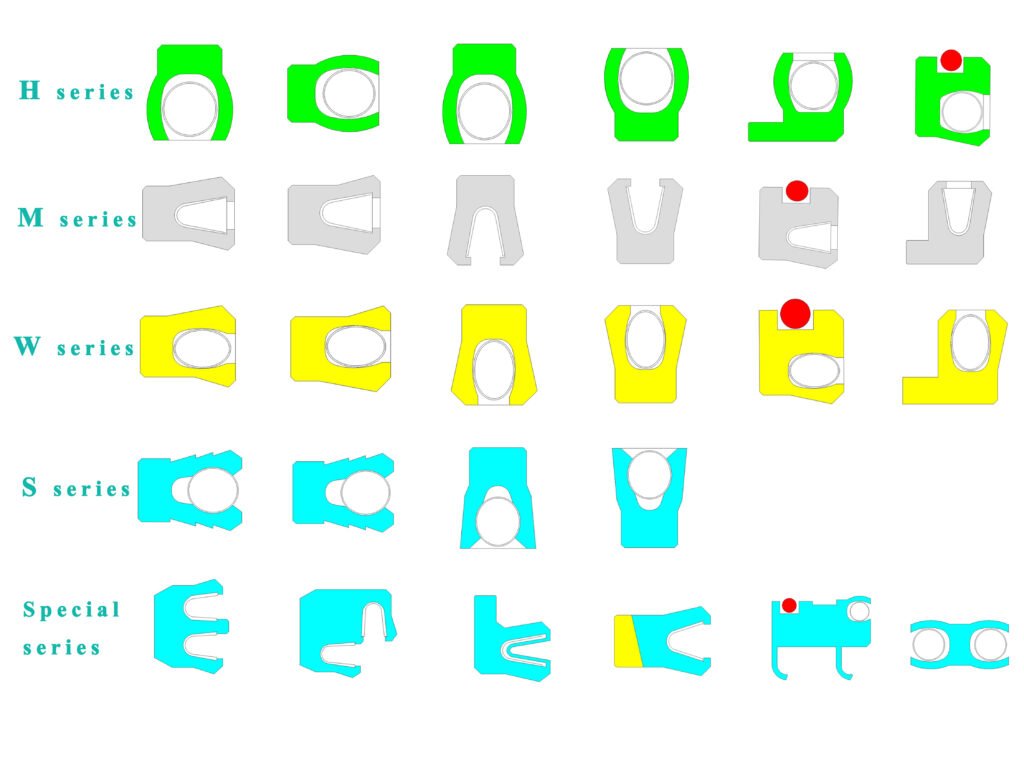

Spring Types

As it was described earlier, the main function of the spring energizer is to provide a radial force at the seal jacket sealing points when installed into the seal cavity. This feature compensates for materials with low memory/elasticity. In addition, the spring energizer adds flexibility to the jacket sealing points to compensate for eccentricity and material wear out as well.

Spring energized seals are available with a variety of spring energizers, each with different mechanical characteristics to meet specific application requirements.

“There are several factors that guide the spring selection:

Surface speed

Frictional load and friction

Wear

Operating temperature

Sealability

Equipment and operation factors

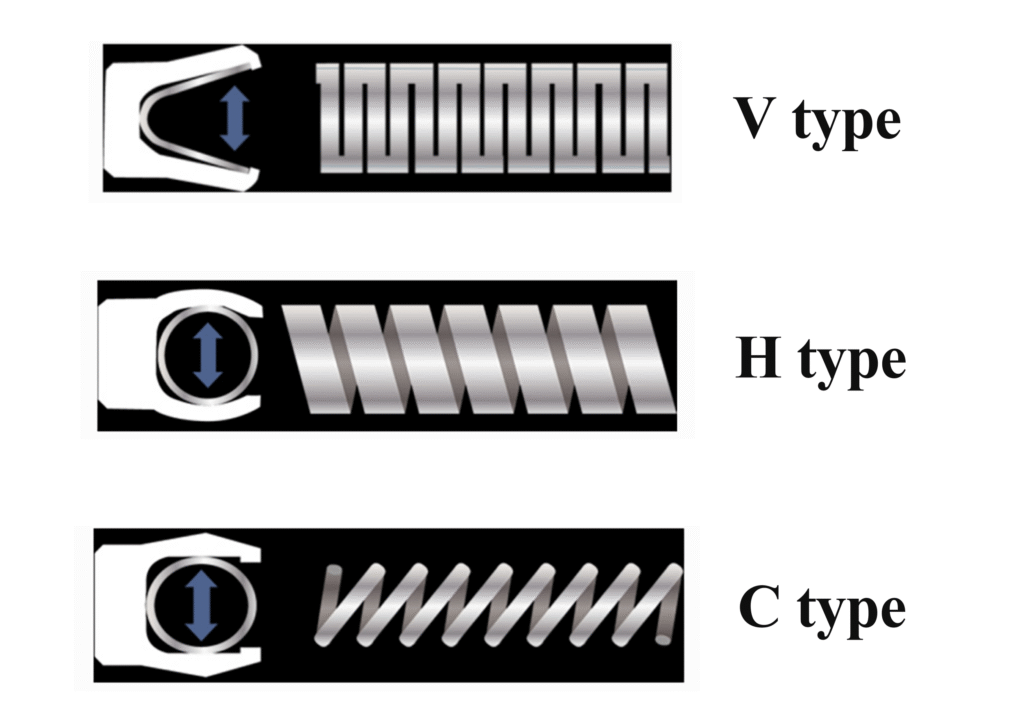

“The most typical spring designs used in spring energized seals:

Cantilever Spring (V type)

Helical Wound Spring (H type)

Elliptical Coil Spring (C type)“

Features of V type spring

• The V-shaped spring enables the PTFE or UHMW-PE sealing lip at the long arm end to “press against” the sealed surface, providing a moderate sealing force.

• With its compact design, it can be directly installed in standard O-ring grooves.

• It fully complies with the AS 568A standard, and a backup ring can be added if necessary.

• The standard material of the spring is stainless steel; other materials with better corrosion and heat resistance, such as alloys like Hastelloy® and Elgiloy®, can be selected based on application conditions.

• Temperature resistance range: -150°C ~ 260°C

• The standard type is suitable for pressure ranging from vacuum to 210 kg/cm², while the pressure resistance can reach up to 700 kg/cm² when equipped with a specially shaped backup ring.

• When applied in environments with abrasive particles, a scraper-shaped sealing lip can be selected.

Application Occasions:

• Shaft and piston sealing for reciprocating mechanisms

• Rotating shaft sealing, with a maximum speed of 4 m/s

• For static sealing, the sealing groove allows for larger tolerances and misalignment

• Face seals are suitable for application environments with internal pressure or external pressure

• The maximum operating temperature for dynamic sealing can reach 260°C

Features of H type spring

• High spring constant, suitable for medium and high load applications

• Each coil of the spiral spring bears force evenly

• Can replace standard inch-sized O-rings without modifying the groove dimensions

• Standard material: stainless steel spring; alternative materials such as Elgiloy® and Hastelloy® alloys are also available

• Temperature resistance range: -150°C ~ 300°C

• The standard type is suitable for pressures ranging from vacuum to 210 kg/cm², and can withstand pressures up to 700 kg/cm² when equipped with a specially shaped backup ring

• Not suitable for sealing grooves with large tolerances or misalignment

Application Occasions:

• Static shaft and piston sealing

• Slow-speed dynamic sealing applications, with a speed below 3 meters per minute (mpm)

• Face seals for internal and external pressure

• Sealing for vacuum and refrigerant

Features of C type spring

• The C-type (slanted coil) spring maintains a constant load within a relatively large deformation range.

• C-type springs with different load characteristics can be selected according to application requirements.

• Compatible with grooves for O-rings that meet MIL-G-5514 and AS 568 standards.

• Standard spring material: 302 C-type stainless steel; Hastelloy® alloy is also available as an alternative.

• Suitable for application environments with internal or external pressure.

• Not suitable for environments with abrasive particles.

Application Occasions:

• Shaft and piston sealing for reciprocating mechanisms.

• Rotating shaft sealing, with a maximum speed of 1.5 m/s.

• Applications sensitive to friction force.

• Suitable for applications with a diameter of < 1/2″ and a cross-section of < 3/32″.

• The sealing groove allows for relatively large tolerances and misalignment.