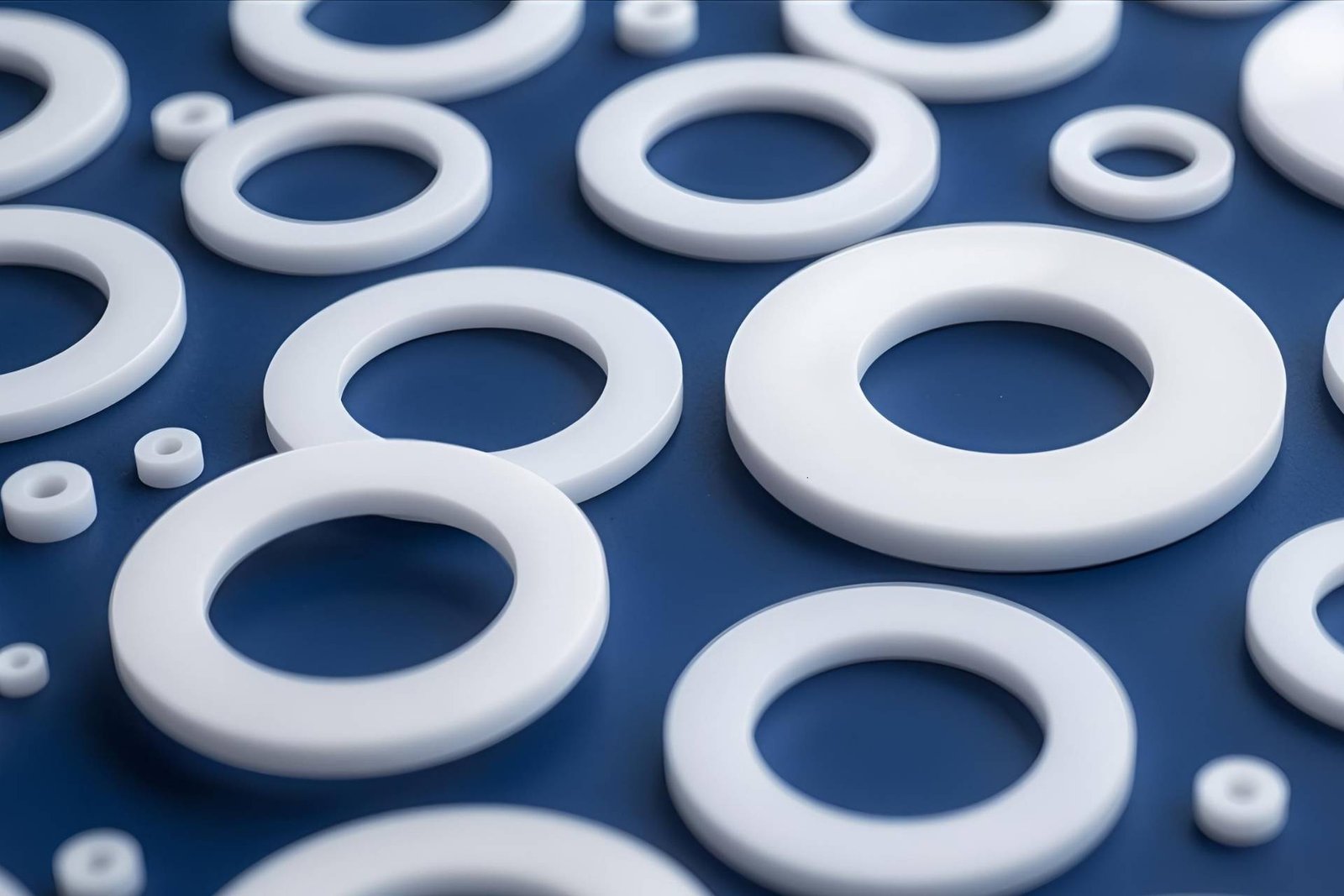

聚四氟乙烯(PTFE)垫圈是现代工程中不可或缺的部件,其独特的性能组合使其适用于最苛刻的工业环境。其优异的化学惰性、宽广的工作温度范围(-200°C 至 +260°C)和极低的摩擦系数,使其成为卓越的密封和绝缘解决方案。然而,这些关键部件的全球市场并不是单一的。它包括一个复杂的企业生态系统,从原材料创新企业到高度专业化的制造企业。本分析报告对聚四氟乙烯垫圈的生产情况进行了结构化概述,对主要企业进行了分类,以帮助工程师和采购专家做出明智的采购决策。.

The PTFE Manufacturing Ecosystem: From Resin to Ring

Understanding the PTFE washer supply chain is crucial to appreciating the different types of manufacturers. The process begins with a few global chemical corporations that produce the base PTFE resin. This raw material is then processed by a broader group of companies through methods like compression molding, isostatic molding, or skiving from billets to create stock shapes (rods, tubes, sheets). Finally, these stock shapes are machined into finished washers by a diverse array of fabricators. This tiered structure gives rise to three primary categories of manufacturers, each with distinct strengths and market positions.

Category 1: Raw Material Innovators & Integrated Giants

At the apex of the supply chain are the multinational chemical corporations that invented and continue to innovate fluoropolymer science. These companies not only produce the base PTFE resins but often have divisions that manufacture high-performance, semi-finished and finished components. Their primary competitive advantage lies in their complete control over material science, from polymerization to final product, ensuring unparalleled material consistency and quality.

- The Chemours Company: As a spin-off from DuPont, Chemours inherited the iconic Teflon™ brand. Their role is foundational, setting the quality benchmark for PTFE resins worldwide. While they primarily supply resin to downstream processors, their influence on material standards and application development is immense.

- 3M (Dyneon™): 3M is a major force in fluoropolymers with its Dyneon™ brand of PTFE. Their focus is on high-performance grades, including modified PTFE and compounds, catering to industries like automotive, chemical processing, and electronics. Their integrated approach allows them to develop materials and components concurrently for specific, challenging applications.

- Daikin Industries: A leading global producer of fluorochemicals, Daikin offers a comprehensive portfolio of POLYFLON™ PTFE resins. Their strength is in providing a wide variety of grades, including fine powders for paste extrusion and granular resins for molding, giving processors extensive options for manufacturing diverse types of PTFE washers.

Sourcing from or through the channels of these giants is ideal for applications where material traceability and certified performance to the highest standards are non-negotiable.

Category 2: Specialized Sealing Technology Leaders

This category consists of large, engineering-focused companies whose core business is sealing technology. While they may not produce the raw PTFE resin, they possess profound expertise in material compounding, product design, and application engineering. They purchase base resins and then create proprietary filled PTFE compounds to enhance specific properties like wear resistance, creep resistance, or thermal conductivity. These specialists serve industries where a standard washer is insufficient and an engineered sealing solution is required.

- 派克汉尼汾公司: As a global leader in motion and control technologies, Parker’s Engineered Materials Group offers an extensive range of PTFE seals and washers. Their strength lies in their vast catalog of standard and custom solutions, backed by a global distribution network and extensive engineering support for industries from aerospace to life sciences.

- 特瑞堡密封系统: Trelleborg excels in developing advanced polymer seals for critical applications. Their Turcon® line of proprietary PTFE-based materials is engineered for extreme conditions in oil & gas, aerospace, and automotive systems. They focus on providing highly engineered solutions rather than just components.

- Garlock Sealing Technologies: Garlock is renowned for its high-performance fluid sealing products. Their GYLON® series, a restructured PTFE with superior cold flow resistance, is a prime example of value-added manufacturing. They specialize in creating reliable gasketing and sealing for the chemical processing and power generation industries.

原生聚四氟乙烯

Glass-Filled

Carbon-Filled

Bronze-Filled

Category 3: Custom Fabricators and Niche Specialists

This is the largest and most diverse group, comprising companies that specialize in the precision machining of PTFE and other plastics from stock shapes. Their core competency is not material science innovation but manufacturing excellence. These fabricators are essential for providing custom-sized washers, rapid prototyping, and cost-effective solutions for small to medium-volume orders. They offer flexibility and responsiveness that larger corporations often cannot match. A professional 密封公司 in this category, such as SPARTA 密封件, leverages its focused expertise to provide tailored sealing solutions, working closely with clients to meet precise specifications for fit and function. These specialists are the backbone of the custom sealing industry, ensuring that every unique application has access to a perfectly dimensioned and appropriate sealing component.

When selecting a manufacturer from this category, it is critical to evaluate their capabilities and quality systems. Look for evidence of a robust quality management system (e.g., ISO 9001 certification), advanced CNC machining capabilities, and a proven track record within your specific industry.

| Selection Criterion | Global Conglomerate | Sealing Specialist | Custom Fabricator |

|---|---|---|---|

| Application Type | High-volume, standard parts | Critical, high-performance systems | Custom dimensions, prototypes, low-volume |

| Key Strength | Scale, cost, global logistics | Engineering expertise, proprietary materials | Flexibility, speed, customization |

| Technical Support | Standardized, catalog-based | In-depth, application-specific consultation | Manufacturing-focused, design for manufacturability |

| Material Traceability | Excellent (vertically integrated) | Very Good (certified suppliers) | Varies (request certification) |

| Ideal For | OEMs, large-scale production | Aerospace, Oil & Gas, Chemical Processing | MRO, R&D, specialized machinery |

Conclusion: Matching the Manufacturer to the Mission

The global PTFE washer manufacturing landscape is a layered and specialized field. There is no single “best” manufacturer; the optimal choice is intrinsically linked to the specific requirements of the application. For engineers and buyers, the task is to identify whether their priority is the ultimate material science assurance from an integrated giant, the deep application engineering from a sealing technology leader, or the agility and customization offered by a specialist fabricator. By understanding these distinct categories and their core competencies, organizations can forge the right partnerships to ensure sealing integrity, optimize equipment performance, and achieve long-term operational reliability.

常见问题(FAQ)

Virgin PTFE washers are made from 100% pure Polytetrafluoroethylene resin and offer the highest chemical resistance and lowest coefficient of friction. Filled PTFE washers incorporate additives like glass fiber, carbon, or bronze into the PTFE matrix. These fillers enhance specific mechanical properties such as compressive strength, wear resistance, and thermal conductivity, making them suitable for more demanding physical applications, though sometimes at the expense of some chemical resistance.

Choosing the right manufacturer depends on your specific needs. For large-scale, standard applications, a global conglomerate may offer the best pricing and logistics. For highly specialized or demanding applications, a dedicated sealing technology company provides deep engineering expertise. For unique dimensions, small batches, or rapid prototyping, a custom fabricator is often the ideal choice. Key criteria to evaluate include material certifications (e.g., ISO 9001), customization capabilities, industry-specific experience, and the level of technical support provided.

Yes, functionally they are the same material. PTFE (Polytetrafluoroethylene) is the generic chemical name for the fluoropolymer. Teflon™ is the registered trademark name for PTFE discovered and commercialized by DuPont (now The Chemours Company). While all Teflon™ washers are made of PTFE, not all PTFE washers can be marketed under the Teflon™ brand name. The term ‘PTFE washer’ is the technically correct and universally accepted industry term.

参考文献和进一步阅读

The analysis and information presented in this article were compiled by synthesizing data from leading industry resources and manufacturers. The following sources were consulted to understand the market landscape and technical properties of PTFE, providing a foundation for the analytical framework presented.

- 特瑞堡密封系统: Technical library and material data sheets for Turcon® materials, providing insights into engineered PTFE compounds. (e.g., trelleborg.com/en/seals)

- 派克汉尼汾公司: Product catalogs and engineering blogs from the Engineered Materials Group, illustrating the breadth of applications for PTFE seals. (e.g., parker.com/emg)

- Garlock Sealing Technologies: Information on GYLON® restructured PTFE, highlighting innovations in enhancing PTFE’s mechanical properties. (e.g., garlock.com)

- Thomasnet: Supplier directories and company profiles, used to identify the scope and scale of custom fabricators in North America. (e.g., thomasnet.com)

- Specialty Plastics, Inc.: Technical articles comparing various filled PTFE grades, which informed the data visualization. (e.g., specialtyplasticsinc.com)